Materyèl Asye Do-Kay Dx53D Zenk Kouvwi Corrugated Galvanized Steel Do-Kay Fèy

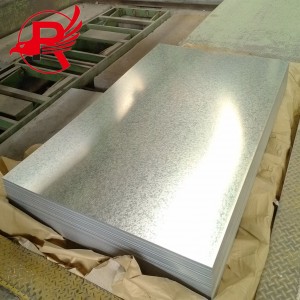

Plak asye galvanize cho pou plonjeMateryèl la bèl, lis, epi li gen bon rezistans korozyon. Li lajman itilize pou kouvri tout kò machin nan. Nou ka di ke fèy galvanize yo itilize tout kote yo bezwen plak asye sou machin yo, tankou plafon machin, panno konpatiman, elatriye. Fòs ak rezistans fèy galvanize yo reflete nan divès resipyan, patisyon kabin bato, kloti gran wout, elatriye nan endistri sa a.

Plastisite a nanFèy asye galvanizeLi trè apwopriye tou nan endistri mèb epi li ka itilize nan fabrikasyon lanp, biwo, kontwa, etajè liv ak lòt pwodwi.

Endistri konstriksyon:Plak asye galvanizeYo gen pèfòmans ekselan nan soude, flite ak prevansyon rouye, epi yo pral itilize nan balkon, rebò fenèt, depo ak pòt vole twati.

| Nòm teknik | EN10147, EN10142, DIN 17162, JIS G3302, ASTM A653 |

| Klas asye | Dx51D, Dx52D, Dx53D, DX54D, S220GD, S250GD, S280GD, S350GD, S350GD, S550GD; SGCC, SGHC, SGCH, SGH340, SGH400, SGH440, SGH490, SGH540, SGCD1, SGCD2, SGCD3, SGC340, SGC340, SGC490, SGC570; SQ CR22 (230), SQ CR22 (255), SQ CR40 (275), SQ CR50 (340), SQ CR80(550), CQ, FS, DDS, EDDS, SQ CR33 (230), SQ CR37 (255), SQCR40 (275), SQ CR50 (340), SQ CR80 (550); oubyen Kliyan an Egzijans |

| Epesè | egzijans kliyan an |

| Lajè | dapre egzijans kliyan an |

| Kalite kouch | Asye galvanize cho tranpe (HDGI) |

| Kouch Zenk | 30-275g/m2 |

| Tretman Sifas | Pasivasyon (C), Luilaj (O), Sele lak (L), Fosfatasyon (P), Pa trete (U) |

| Estrikti Sifas | Kouch pay nòmal (NS), kouch pay minimize (MS), san pay (FS) |

| Kalite | Apwouve pa SGS, ISO |

| ID | 508mm/610mm |

| Pwa bobin | 3-20 tòn metrik pou chak bobin |

| Pakè | Papye ki reziste dlo a se anbalaj enteryè a, asye galvanize oswa fèy asye kouvwi se anbalaj ekstèn lan, plak pwoteksyon bò a, epi vlope pa sèt senti asye.oswa selon egzijans kliyan an |

| Mache ekspòtasyon | Ewòp, Afrik, Azi Santral, Azi Sidès, Mwayen Oryan, Amerik di Sid, Amerik di Nò, elatriye |

| Tablo Konparezon Epesè Kalib | ||||

| Kalib | Dous | Aliminyòm | Galvanize | Nerjaveèi |

| Kalib 3 | 6.08mm | 5.83mm | 6.35mm | |

| Kalib 4 | 5.7mm | 5.19mm | 5.95mm | |

| Kalib 5 | 5.32mm | 4.62mm | 5.55mm | |

| Kalib 6 | 4.94mm | 4.11mm | 5.16mm | |

| Kalib 7 | 4.56mm | 3.67mm | 4.76mm | |

| Kalib 8 | 4.18mm | 3.26mm | 4.27mm | 4.19mm |

| Kalib 9 | 3.8mm | 2.91mm | 3.89mm | 3.97mm |

| Kalib 10 | 3.42mm | 2.59mm | 3.51mm | 3.57mm |

| Kalib 11 | 3.04mm | 2.3mm | 3.13mm | 3.18mm |

| Kalib 12 | 2.66mm | 2.05mm | 2.75mm | 2.78mm |

| Kalib 13 | 2.28mm | 1.83mm | 2.37mm | 2.38mm |

| Kalib 14 | 1.9mm | 1.63mm | 1.99mm | 1.98mm |

| Kalib 15 | 1.71mm | 1.45mm | 1.8mm | 1.78mm |

| Kalib 16 | 1.52mm | 1.29mm | 1.61mm | 1.59mm |

| Kalib 17 | 1.36mm | 1.15mm | 1.46mm | 1.43mm |

| Kalib 18 | 1.21mm | 1.02mm | 1.31mm | 1.27mm |

| Kalib 19 | 1.06mm | 0.91mm | 1.16mm | 1.11mm |

| Kalib 20 | 0.91mm | 0.81mm | 1.00mm | 0.95mm |

| Kalib 21 | 0.83mm | 0.72mm | 0.93mm | 0.87mm |

| Kalib 22 | 0.76mm | 0.64mm | 085mm | 0.79mm |

| Kalib 23 | 0.68mm | 0.57mm | 0.78mm | 1.48mm |

| Kalib 24 | 0.6mm | 0.51mm | 0.70mm | 0.64mm |

| Kalib 25 | 0.53mm | 0.45mm | 0.63mm | 0.56mm |

| Kalib 26 | 0.46mm | 0.4mm | 0.69mm | 0.47mm |

| Kalib 27 | 0.41mm | 0.36mm | 0.51mm | 0.44mm |

| Kalib 28 | 0.38mm | 0.32mm | 0.47mm | 0.40mm |

| Kalib 29 | 0.34mm | 0.29mm | 0.44mm | 0.36mm |

| Kalib 30 | 0.30mm | 0.25mm | 0.40mm | 0.32mm |

| Kalib 31 | 0.26mm | 0.23mm | 0.36mm | 0.28mm |

| Kalib 32 | 0.24mm | 0.20mm | 0.34mm | 0.26mm |

| Kalib 33 | 0.22mm | 0.18mm | 0.24mm | |

| Kalib 34 | 0.20mm | 0.16mm | 0.22mm | |

1. Ki pri ou yo?

Pri nou yo ka chanje selon rezèv la ak lòt faktè mache a. N ap voye ba ou yon lis pri ki ajou apre konpayi ou an kontakte nou.

nou pou plis enfòmasyon.

2. Èske ou gen yon kantite minimòm pou kòmande?

Wi, nou egzije pou tout kòmand entènasyonal yo gen yon kantite minimòm pou kòmande. Si w ap chèche revann men nan kantite pi piti, nou rekòmande pou w vizite sit entènèt nou an.

3. Èske ou ka bay dokiman ki enpòtan yo?

Wi, nou ka bay pifò dokiman tankou Sètifika Analiz/Konfòmite; Asirans; Orijin, ak lòt dokiman ekspòtasyon kote sa nesesè.

4. Ki tan livrezon mwayèn lan?

Pou echantiyon yo, tan livrezon an se anviwon 7 jou. Pou pwodiksyon an mas, tan livrezon an se 5-20 jou apre yo fin resevwa peman depo a. Tan livrezon yo vin efektif lè

(1) nou resevwa depo ou a, epi (2) nou gen apwobasyon final ou pou pwodwi ou yo. Si tan livrezon nou yo pa koresponn ak dat limit ou a, tanpri pale sou bezwen ou yo lè w ap fè vant lan. Nan tout ka, n ap eseye satisfè bezwen ou yo. Nan pifò ka yo, nou kapab fè sa.

5. Ki kalite metòd peman ou aksepte?

30% davans pa T/T, 70% pral anvan chajman debaz sou FOB; 30% davans pa T/T, 70% kont kopi BL debaz sou CIF.